XPS and electrochemistry to understand diffusion of X60 steel

Publication: R. Hannachi, D. Biggio, B. Elsener, M. Fantauzzi, N. Zacchetti, A. Rossi, A Contribution of XPS and Electrochemistry to the Understanding of Hydrogen Diffusion in X60 Steel, Coatings 15 (2025) 442 doi: 10.3390/coatings15040442

X60 API 5L is one of the typical medium to high strength pipeline steels of the oil and gas industry that might be used in the future for green hydrogen storage and transportation. It is thus essential to know its mechanical, electrochemical and hydrogen permeation properties. In the framework of the e.INS WP 7 project “Study of hydrogen permeation barriers for the safe storage and transport of green hydrogen” hydrogen permeation of X60 API 5L steel was studied with an electrochemical procedure to determine its diffusion coefficient and hydrogen solubility.

The effective hydrogen diffusion coefficient Deff was determined from the hydrogen detection curves (figure) with the breakthrough time tb (or the time lag) according to the equation in the figure. With the sample thickness L = 2 mm the results (table) were in good agreement with literature.

| Deff (m2s-1) | Deff (m2s-1) | H C0 ppm | |

| H C X60 steel | 2.4 (0.4) 10-10 | 2.8 (0.2 10-10 | 0.66 (0.02) |

| H MP X60 steel | 2.0 (0.4) 10-10 | 2.9 (0.5) | 0.8 (0.1) |

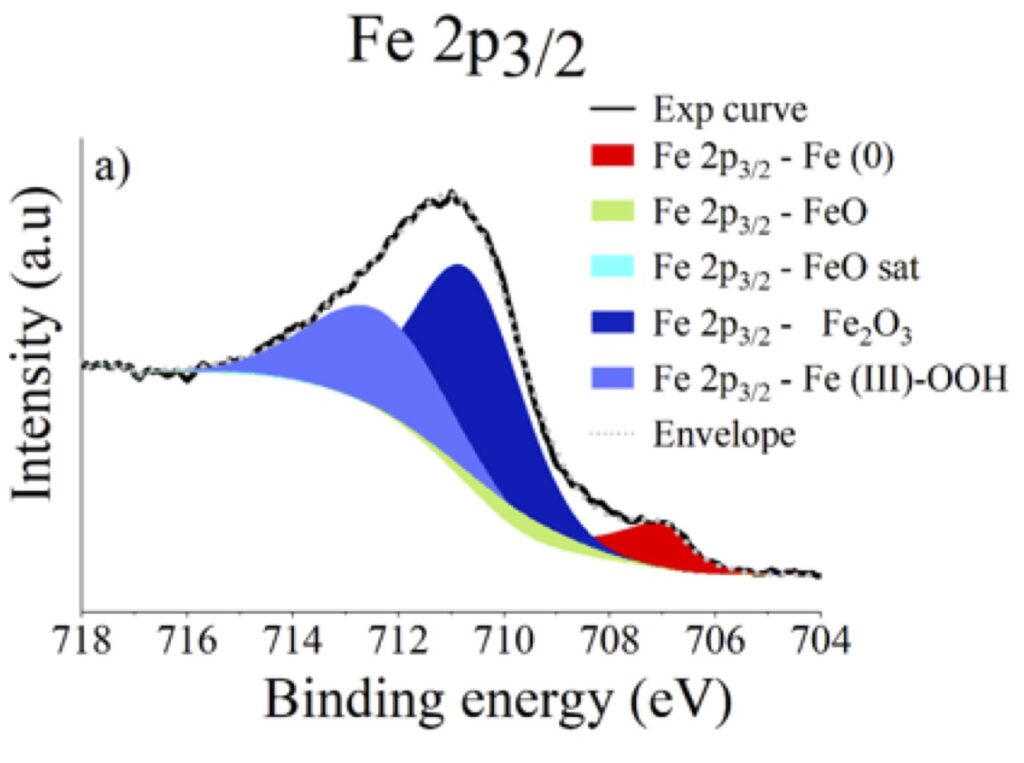

Thickness and composition of the oxide film on the X60 steel were determined by X-ray photoelectron spectroscopy (XPS). The high resolution Fe2p3/2 spectra (figure) were fitted with four peaks corresponding to metallic iron (706. 8 (0.1) eV), iron oxide FeO (709.4 (0.1) ev), Fe2O3 (710.6 (0.1) eV) and FeOOH (712.5 (0.1) eV).