Nano-layered surfaces

Nanostructured surfaces are often the foundation of new and remarkable material properties, such as corrosion resistance resulting from the spontaneous formation of a protective oxide film, or the functionalization of a metallic or oxide substrate with adsorbed molecules to enhance, for example, biocompatibility. Both the composition of the film and the interface with the underlying alloy govern the desired properties of the nanostructured surface; for this reason, it is important to understand the depth concentration profile at the interface.

Reconstruction of the concentration depth profile from ARXPS measurements

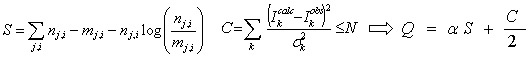

The Maximum Entropy Method (MEM) allows for a reconstruction that fits the data obtained from angle-resolved photoelectron spectroscopy (ARXPS), while containing the minimum amount of structure necessary to do so—since it is neither necessary nor desirable to fit every detail of the noise.

Angular resolved XPS (ARXPS) is at the basis for the experimental determination of thickness and composition of the film. MEM finds the concentration depth profile. This is done by maximising the overall logaritmic probability function, Q obtained by optimising the balance between maximum entropy, S and minimum chi-squared, C.

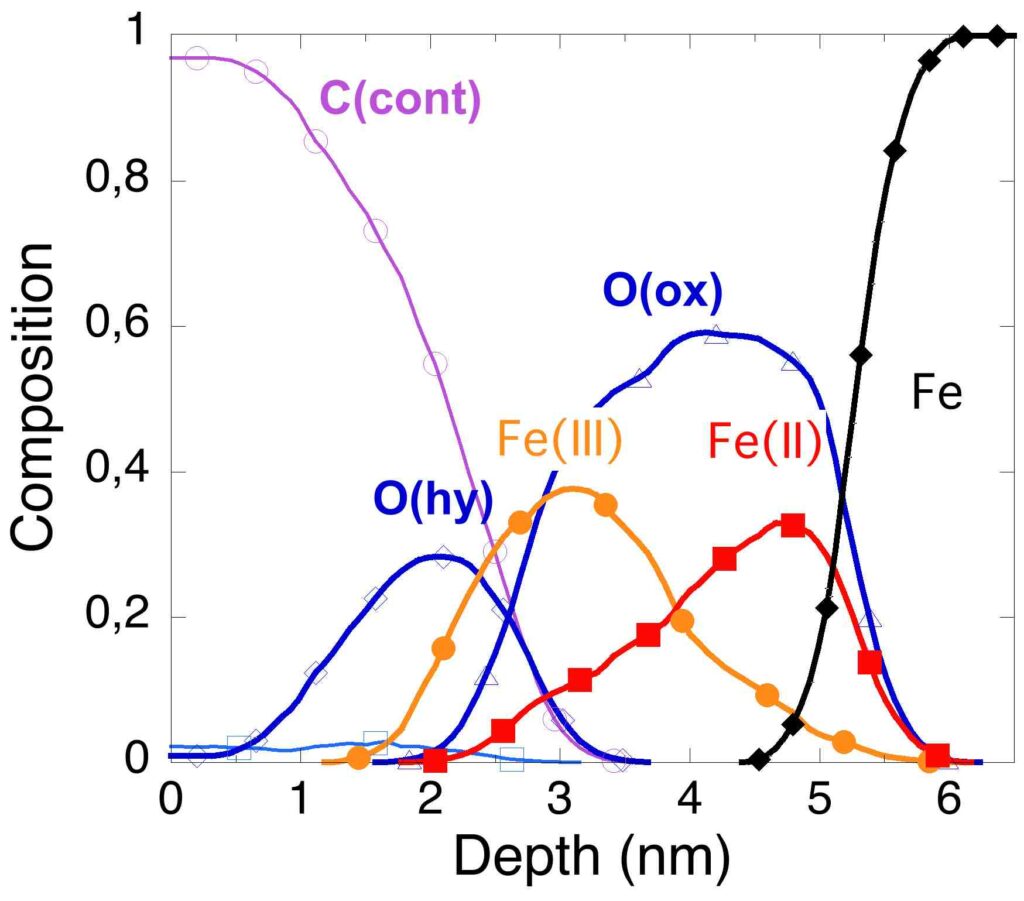

Application to surface films on iron

The MEM algorithm was applied to ARXPS data from iron samples to investigate the in-depth variations in the composition and chemical state of the nanosized oxy-hydroxide film naturally grown on the iron surface. The resulting surface film presents a complex multilayer structure with concentration gradients. Fe(III) hydroxide in the outer, Fe(II)oxide in the inner part of the manometric surface film. The total thickness, including hydrocarbon contamination, is about 5.5 nm.

Publication: M.Olla, G. Navarra, B. Elsener and A. Rossi, Non-destructive in-depth composition profile of oxy-hydroxide nanolayers on iron surfaces from ARXPS measurement, Surface Interface Analysis 38 (2006) 964 – 974

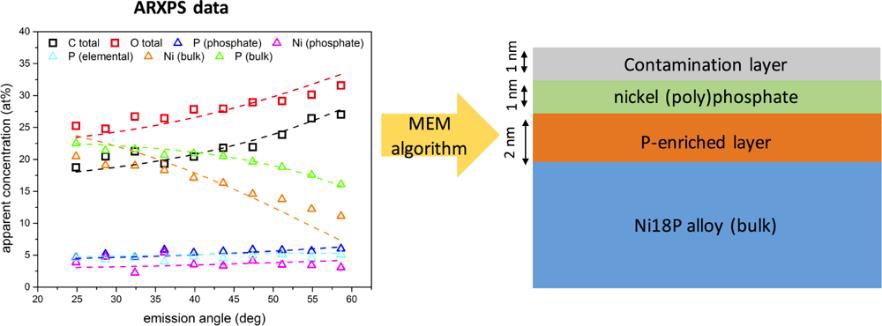

Application to surface films on electroless Ni-P alloys

The main findings were that the very high corrosion resistance of Ni-P coatings (and also of amorphous Ni-P ribbons prepared by rapid quenching) is due to a nickel-phosphate surface layer of about 1 nm thickness and beneath a highly phosphorus enriched layer of about 2 nm that block the dissolution of nickel from the bulk of the Ni-P layer.

Publication: Mariano Andrea Scorciapino, Marzia Fantauzzi, Maura Crobu, Gabriele Navarra, Bernhard Elsener, Antonella Rossi, Nanolayered Surface Films on Ni18P Alloy in Sulfate Solutions by the Maximum Entropy Method, ACS Omega 2 (2017) 7790–7802. DOI: 10.1021/acsomega.7b00958